- Who We Are

-

Our Work

-

Educational

- Brooks School- George and Evanthea Demoulas Family Boathouse

- Riverbend School - Gym and Schoolhouse

- Lesley University- Animation Studio

- Middlesex School- Bass Arts Pavilion and Danoff Visual Arts Center

- Nashoba Brooks School- Sureau Family Discovery Barn

- The Southport School- Arts and Music Building

- Senior Living

- Hospitality

-

Healthcare

- Partners Urgent Care

- Yale New Haven Health- Medical Office Building

- The Hospital of Central Connecticut - Advanced Wound and Hyperbaric Medicine Center

- Connecticut Children's - Infusion Center and Gastrointestinal Clinic

- Connecticut Children's - Specialty Care Center

- MidState Medical Center- Post-Anesthesia Care Unit Expansion & Renovation

- Commercial

- Specialty Work

-

Educational

- How We Do It

- Our Blog

- Industry Tidbits

- Join Our Family

- Contact Us

Ground Penetrating Radar

June 28th, 2016

Does your project require cutting into concrete? If so, there’s a simple way to avoid project delays, cost overruns and worker injuries. Use ground penetrating radar to map out what’s underneath the concrete before cutting into it.

What is it?

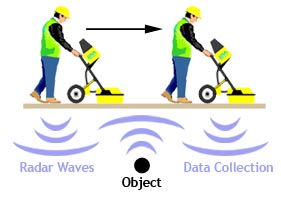

Ground penetrating radar is an affordable, easy-to-use process to find rebar, post-tension cables, conduit or pipes under concrete. Basically ground penetrating radar equipment sends pulses of radar energy into the ground through an antenna. Metals underground completely reflect the signal, while materials with a high dielectric, such as plastic, will slow the radar wave. The equipment records the readings, then the operator can map out the obstacles that were found.

Why do it?

Ground penetrating radar is an important tool to help avoid problems when working with existing concrete. If you didn’t have the use of this tool built into your project schedule, it may cause minor delays, however, its use avoids the potential for much longer, costly delays. Scanning helps to avoid the monetary cost of damaging the structure or cutting into existing utilities, such as electrical wires or water lines, and the time spent to repair that damage. Using ground penetrating radar also minimizes the risk of electrocution or other injury to the worker.

Case Study: Bakery on Main

At Bakery on Main, there were no as-built drawings of the former warehouse building, and the project required extensive slab cutting. There was no way we were going to start that work without knowing what was underneath the concrete! We mapped out a 1500 sf area in four hours. Ground penetrating radar was an invaluable tool for us to use based on the low cost of the service and the tight construction schedule. It gave us peace of mind and confidence to perform the work that needed to be done.

Case Study: Concord Academy

While working on an addition and renovation at Concord Academy, we needed to increase the size of the existing window openings to accommodate the new, larger windows. When we peeled back the drywall and siding, we saw an unusual header detail in the CMU and foundation. We didn’t want to cut out the larger window openings until we knew the existing building was properly reinforced.

We used ground penetrating radar to scan the exterior wall of the building. The structural engineer studied the results to determine the potential for interfering with the structural integrity of the building. As it turned out, we needed to add structural support to support the weight of the precast plank floors above before cutting out the window openings. Instead of adding a lintel, which would have required shoring at all 16 windows, we came up with a solution that saved money and made the work safer to execute. The cost of scanning was far less than it would have cost to shore all 16 window locations. We started this process early enough in the schedule, that no additional time was added to the schedule while coming up with a solution to the problem.

Summary

Using ground penetrating radar before cutting into concrete is becoming more and more routine. For a low fee, you get immediate results and the risks of cutting into concrete can be substantially reduced and in some cases eliminated.

Contact us to learn more about how C.E. Floyd can help you with your next construction project.